Flexible MOQ injection moulding solutions for high precision plastic components, made in all engineering and high-performance materials.

Faster Production. Smarter Moulding

Why Choose Marcopolo for Injection Moulding?

No MOQ-Linked Production

Start production from just 50 parts; we scale output based on your demand, not minimum quantity constraints.

High-Performance Plastics

We mould everything from standard polymers to advanced plastics like PEEK, ULTEM, & PPS for high-performance applications.

Contract Manufacturing

End-to-end services include part finishing, assembly, ultrasonic welding, and printing for plug-and-play deliveries.

Proven Quality Management

ISO 9001-certified with CMM/VMM inspections and multi-stage audits to ensure consistent quality across all production runs.

Speed Meets Accuracy

From Design to Delivery : Moulds That Meet the Global Standards

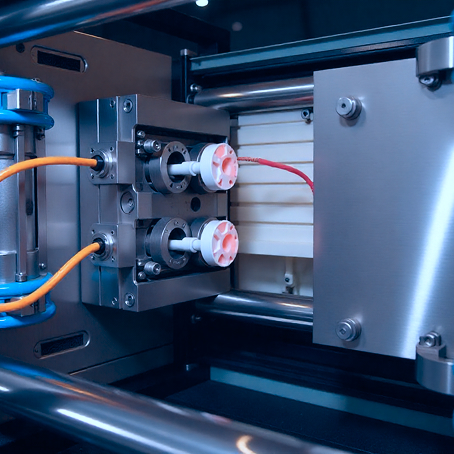

Injection Moulding Machines (20T to 1000T)

From precision micro-moulding (1g) to large components (up to 2,000g), we handle a wide range of shot sizes and complexities.

Insert & Overmoulding

Integrate metal inserts or create multi-material parts with reduced assembly, for both functional and cosmetic needs.

Low MOQ Flexibility

Unlike commercial suppliers, we support batch sizes as low as 50 units, scaling as needed without minimum quantity pressure.

Post-Moulding Operations

Ultrasonic welding, mechanical assembly, and pad/UV/screen printing are available for plug-and-play supply.

Full Range of Engineering Plastics

ABS, Nylon (PA6, PA66), PP, PC, and POM, sourced from leading global suppliers.

High-Performance Plastics

PEEK, ULTEM™ (PEI), and PPS. It’s used for thermal, structural, and chemically exposed parts in aerospace, medical, and EVs.

Colours & Finishes

Achieve exact brand-matched colours or surface aesthetics through customised pigmentation and optimised processing.

Functional Grade Matching

Material selection guided by use case. It’s ESD-safe, flame-retardant, food-grade, or biocompatible options are available.

Tight Tolerances (Up to ±0.02 mm)

We achieve tolerances as per 2D, with high focus on optimal processing conditions.

Highly Aesthetic Surface Finishes

We ensure zero surface defects in processing, thus making aesthetic parts free from flow marks, sink marks, weld lines, etc.

ISO 9001 QMS

Strong Quality Management system (QMS) with defined Quality Plan from Sample Inspection Report to in-process inspection to PDI Reports.

Contract Manufacturing

Post moulding services like mechanical assembly, pad/ UV/ screen printing, etc. to enable a one-stop solution for plastic component supply.

From Design to Delivery

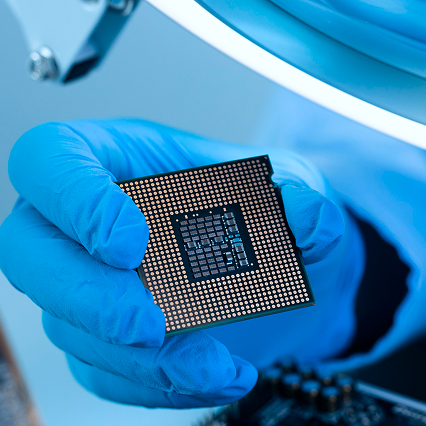

Finely Built Complex Parts for Scalable Production

We go beyond basic moulding to deliver functional, production-ready components that meet the strictest industry standards. We are uniquely positioned to enable clients to make moulded parts in quantities as per their demand, with a Minimum Order Quantity (MOQ) as low as 50 units.

Our team is highly experienced in Moulding components in horizontal and vertical Injection Moulding Machines up to 1000T, with capabilities for insert-moulding, over-moulding and post-moulding assembly operations. Our ISO 9001 QMS ensures a strong focus on quality inspection as per the defined plan to deliver highly accurate parts.

Faster Iterations. Smarter Production

How Leading Companies Are Scaling With Our 3D Printing Solutions

Test Your Design with Confidence for Manufacturing

Testimonials

What Our Clients Say?

Impact Across Industries

Pushing Product Development Boundaries

We Deliver Precision Injection Moulding

Transforming complex designs into production-ready parts with ±0.03mm accuracy.

Schedule a CallExplore ServicesWhat is injection moulding best suited for?

Injection moulding excels in medium to high-volume production where consistency, speed, and part complexity matter. It’s ideal for industries like medical, automotive, aerospace, and consumer electronics, where dimensional accuracy and repeatable performance are crucial.

What is the difference between prototype moulding and production moulding?

Prototype moulding uses soft tools (aluminium or silicone) for low-volume runs and design validation, while production moulding involves hardened steel tools built for high-volume manufacturing.

At Marcopolo, we help you choose the right approach based on your project stage, volume, and budget, thereby ensuring you invest wisely at every step.

Can I get overmoulded or insert-moulded parts?

Yes! We offer both overmoulding (combining soft and rigid zones) and insert moulding (embedding metal or plastic inserts during the process). This reduces post-production assembly and improves part durability and function.