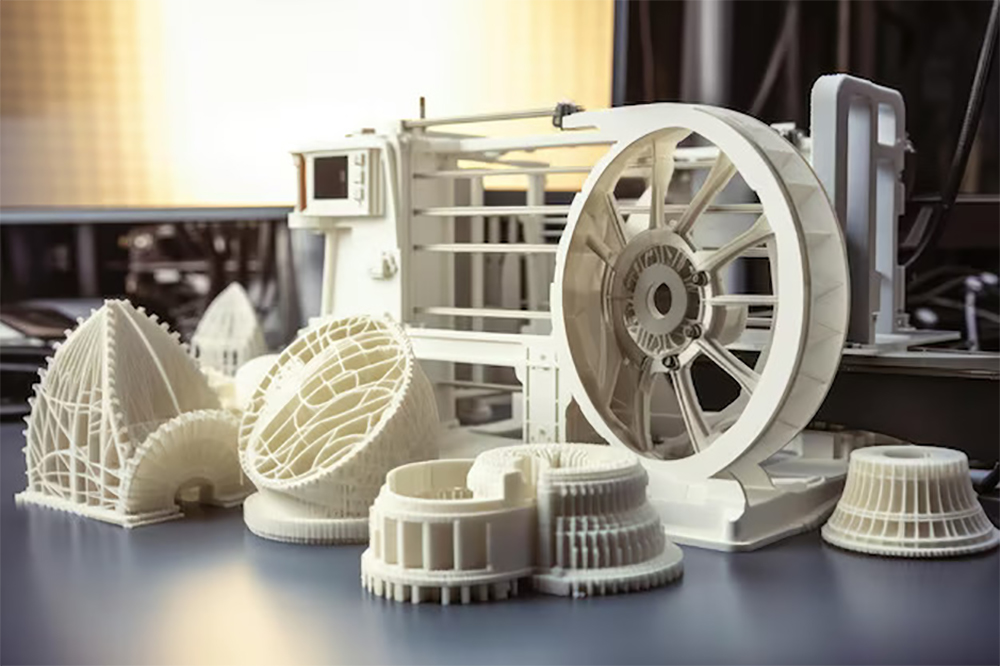

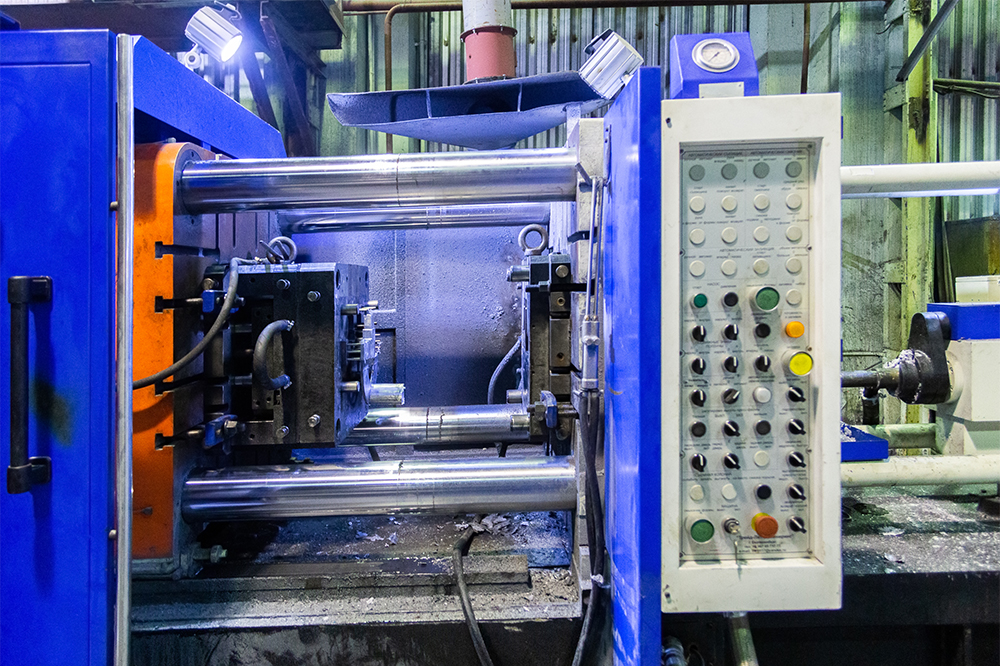

Since 1999, Marcopolo has led rapid prototyping in India. From Kolkata to Pune, they have grown into a powerhouse of engineered plastic parts. Their capabilities span 3D Printing, Rapid Prototyping, Tooling, and Injection Molding. With an ISO 9001 certification, quality is their bedrock. From concept to execution, they ensure precision and perfection. Trusted globally, Marcopolo turns ideas into tangible excellence.

200000

1300

400

25000

Certifications

ISO 9001:2015

Embark on a journey of innovation and precision with Marcopolo. Marcopolo’s certifications aren’t just badges – they’re symbols of commitment to delivering top-notch components that exceed expectations.

Clients in Success

Key Benefits

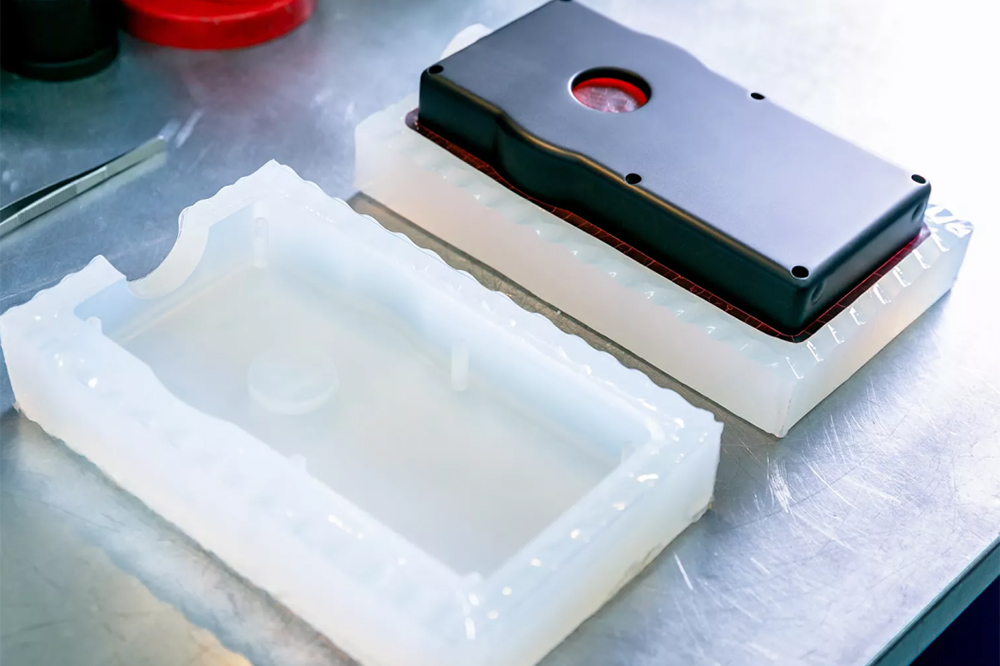

Pre-Production

Runs

Reduce time to market for new product launch by producing components with a Soft Tool in 2 to 6 weeks

One Stop

Solution

Only specialized player offering in-house facilities from Prototyping to Production, and enabled by a network of allied services

Services Offered

Welcome to the heart of innovation at Marcopolo. Marcopolo's services aren't just about manufacturing parts – they're about transforming concepts into tangible, functional reality.

Industries Served

Marcopolo thrives on pushing the boundaries of innovation across a multitude of industries and forms a bridge that connects ideas to reality.

Hear from Our Clients.

Explore firsthand experiences from our valued clients, sharing their success stories, feedback, and how our services made a difference for them.