Marcopolo has three facilities in Pune, Maharashtra and one dedicated 3D Printing facility in Coimbatore, Tamil Nadu.

Facilities & Quality Control

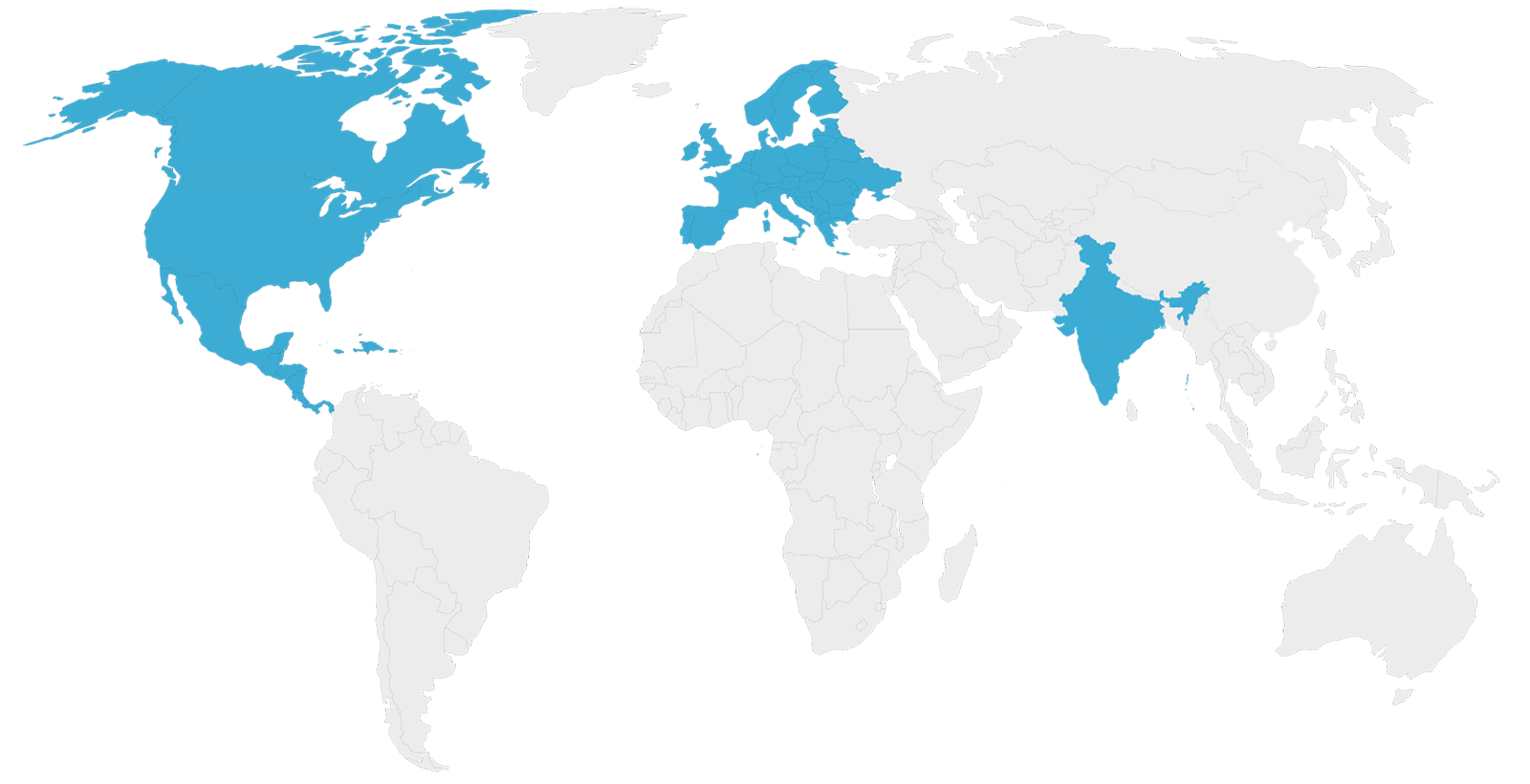

Capability in Managing Global Supply Chains, Exporting Parts and Assemblies to clients Globally

Pune, Maharashtra

Coimbatore, Tamil Nadu

Tool Room

There is a dedicated Tool Room managed by experienced technicians who have delivered 1,000+ prototype and production tools till date. High precision machined components are also manufactured in a variety of materials. Available machinery includes:

- 25 Vertical Milling Centre (VMC) machines

- 5 Electrical Discharge Machines)

- Conventional Machines including Lathe, Drilling, Surface Grinding, M1TR, etc.

Moulding Shop for High Precision Plastic Parts

There is a dedicated facility for Injection Moulding, housing 5 machines ranging from 20 ton to 130 ton. Each machine is equipped with all required accessories to ensure optimal moulding conditions to deliver high quality parts. The Moulding Shop has a dedicated assembly area and storage space, enabling Marcopolo to manufacture and ship fully assembled components to its clients.

Dedicated space for Vacuum Casting Machines and Reaction Injection Moulding Capabilities

We recently added a third factory to create a dedicated space for our vacuum casting machine and Reaction Injection Moulding (RIM) capabilities. On top of these, the facility has additional multi-purpose space to support other service offerings. The Pune facilities also include two SLA 3D Printing machines to enable Rapid Prototyping and Production of master part for Vaccume Casting.

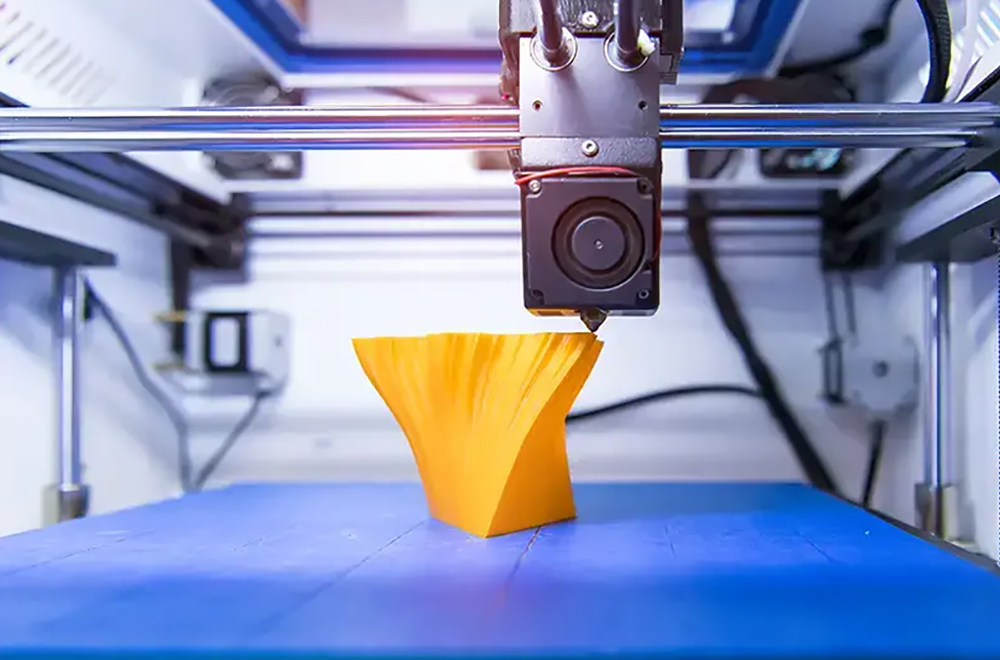

3D Printing Facility in Coimbatore, Tamil Nadu

The 4,000 sqft facility is dedicated for 3D Printing, housing 4 SLA, 1 SLS and 1 MJF machines. It is strategically located to cater to key markets. Markforged 3D Printer is also present in Coimbatore.

Our Commitment to Quality is Demonstrated by our ISO 9001 Certification

Marcopolo deeply understands the need for maintaining high quality standards, having worked on complex and technical components with low tolerance. The company is ISO 9001 certified and has established a Quality Management System, which is a vital part of ensuring quality, customer satisfaction, and continuous improvement.

Each part is inspected in-house and some outsourced measuring equipment are leveraged to meet the desired standards. Advanced equipment like Visual Measuring Machines (VMM) and Coordinate Measuring Machine (CMM) are regularly used to keep a strict control over dimensional accuracy.

Marcopolo is also working towards an IATF and AS 9100 certification in order to meet existing clients’ growing requirements and continuously improve its processes.