From rapid prototyping to functional testing and pre-series production, we accelerate automotive innovation with high-precision, cost-effective plastic components tailored to each system’s performance needs.

Solving Automotive Challenges

From Prototypes to Pre-Series Production

Reducing Development Time

Large-capacity production enables clients to develop and validate parts with up to 50% reduction in lead time.

Functional Parts for Testing & Vehicle Homologation

Injection-moulded parts from soft tooling using production-intent materials for endurance testing and compliance.

Cost-Effective Prototyping

Silicone moulding solutions to produce near-production quality parts for early prototype builds without high tooling costs.

System Level Understanding

Expertise in individual systems ensures that parts meet functional and assembly requirements.

Pre-Series Production

Supply of parts from soft tools helps keep your timelines intact when production tooling faces delays.

Highly Aesthetic Display Models

Scaled or full-size models with showroom-quality finishes for boardrooms, exhibitions, and media display.

What we do

Everything You Need For Automotive

What We Do

Your “One-Stop” Partners: Prototyping to Scalable Production

3D Printing

Rapid prototyping of interior/exterior components for design validation and early-stage testing with short lead times.

Vacuum Casting/RIM

Cost-effective method to create batches of 10–100 aesthetic and functional parts for proto-vehicle builds without hard tooling.

Machining

Ideal for high-accuracy prototypes like brackets, housings, and jigs needed in vehicle validation or test setups.

Injection Moulding

Scalable supply of precision parts (100 to 10,000 units) using engineered polymers, ideal for pre-series production and market launch support.

Rapid Prototyping

SLA, SLS, MJF, Vacuum Casting, RIM and Machining for early fit-form-function validation.

Soft Tooling for Short-Run Moulds

Large Tool Room capacity for Soft Tools developed in 2 – 6 weeks.

Production Tooling

Steel moulds with manufacturability reviews for reliability.

Injection Moulding

Scalable production using in-house machines up to 1000T.

3D Printing Materials

3D Printed prototypes in ABS Equivalent, PC Equivalent, Nylon, PA12, and Glass Filled Nylon materials.

Polyurethane

Engineering Plastics mimicking Polyurethane grades for Vacuum Casting / RIM for plastics and rubber parts.

Tool Steels

Soft tools in aluminium, P20 or EN31, based on production requirements, and Production Tools in P20 HH, H13 steel.

Production Intent Polymer

Exact grade as production intent material through soft tooling, including all engineering and high-performance plastics.

Sheet Metal

Metal parts prototyping for various systems using Sheet Metal, without high investment in press tools.

Metal 3D Printing

3D Printed metal prototypes as an alternative to Casting, Forging, and Machined parts.

Blow Moulding

Blow Moulded tanks, reservoirs, bottles and other components for functional testing.

Vacuum Forming & FRP

Prototypes made using a Wooden tool through Vacuum Forming and FRP.

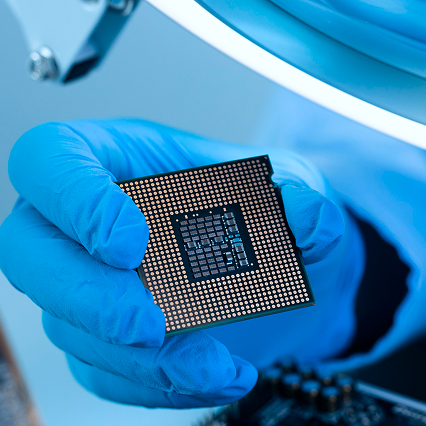

Overview

Your Partner in Auto Innovations

Marcopolo bridges the gap between design and deployment with fast and “accurate to design and intent” plastic manufacturing. With 25+ years of serving automotive clients, our team blends prototyping agility with production rigour to meet homologation, durability, and aesthetic demands.

Let's Bring Your Automotive Breakthrough to Life

Testimonials

What Our Clients Say?

Impact Across Industries

Pushing Product Development Boundaries

Keep Your Production Timeline on Track

Grow from Prototype to Volume Without Changing Partners

Get a QuoteStart PrototypingWhat types of automotive plastic parts can Marcopolo prototype?

Marcopolo prototypes both aesthetic and functional automotive parts like dashboards, housings, clips, and brackets with high dimensional accuracy.

Can you deliver prototype parts in production-grade materials?

Yes. We use soft tooling and injection moulding to deliver parts in production-intent materials like ABS, PC, and Nylon for realistic validation and homologation testing.

Do you offer low-volume manufacturing for automotive parts?

Absolutely. We specialise in low-volume runs (10–100 sets) using silicone moulding or soft tooling to support early-stage development and pilot builds.