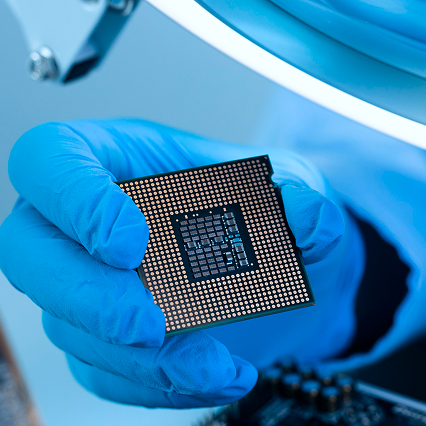

Marcopolo partners with electronics companies as a Contract Manufacturer for Plastic Parts, enabling them to focus on hardware and software. We support from design (DFM advice) through prototyping to scaled production, with our tooling and moulding expertise.

Solving Electronics Challenges

Partner for Plastic Part Development and Manufacturing

Wide Range of Engineering Plastics

We process ESD-safe, scratch-resistant, diffusive, and flame-retardant materials to meet stringent application requirements.

Production-Ready Designs with DFM & Moldflow

Our in-house design team assists with manufacturability reviews and simulations to ensure tooling and part success.

Cost-Efficient Short-Run Tooling

Soft tooling engineered to production-equivalent standards helps reduce tooling investment by up to 50%.

Flexible MOQs for Dynamic Demand

We support product variability with no high minimum order constraints; it’s ideal for startups or fast-paced teams.

Functional Prototypes with Real-World Performance

New designs are tested out with Rapid Prototyping & Soft Tooling before investment in Production Tooling.

Printing, Assembly, and Insert Moulding

Complete solution for plastic parts assembly post-moulding, and pad / UV / screen printing as per design.

What We Do

End-to-End Electronics Manufacturing Support

Prototyping

Ideal for validating new product design, exhibition demo products, pilot batch production.

Soft Tooling for Low to Mid Volumes

Minimise your tooling cost for new product launches and market testing, while getting tool life up to 10,000 shots.

Design for Manufacturability & Mouldflow

Our engineering team collaborates early for faster, smarter product launches.

Production Tooling & Injection Moulding

Batch and Mass Production of plastic components with robust, multi-cavity tools, with production as per your demand.

ABS, PC, PC-ABS, POM, Nylon, etc.

Common in housings, bezels, and general-purpose enclosures.

FR Materials (UL94 V-0 Rated)

Used in power modules and PCB enclosures for flame-retardant protection.

Electronics Specific Plastics

ESD Safe, Diffusivity Grade, Scratch Resistant, UV Stable Materials and more grades to suit functional requirements of the component.

Prototyping Materials

Materials equivalent to ABS, PP, POM, PA, PC for fitment and functional testing.

Pad / UV / Screen Printing

Print artwork and critical labels on the part with high-quality, UV-stable printing.

Tool Texturing

Specific texturing is done on soft and production tools as per aesthetic requirements.

Plastic & Electronics Assembly

Outsource part manufacturing and assembly to get a ready-to-use product with electronics assembled in a plastic part.

Ultrasonic Welding

Join the top and bottom housings with internal assembly by ultrasonic welding with water-resistant bonding strength.

Overview

Your Electronics Production Partner, From Design to Assembly

Marcopolo bridges the gap between R&D and production with material expertise, precision tooling, and flexible volumes for electronics innovators. We leverage our extensive experience in designing and building custom components for electronics, as well as providing internal design support.

Accelerate Your Electronics Project with the Right Prototype Partner

Testimonials

What Our Clients Say?

Impact Across Industries

Pushing Product Development Boundaries

Stay Competitive in a Fast-Moving Market

With fast lead times and flexible tooling, we help you move first

Get a QuoteStart PrototypingWhat types of electronic components can you prototype?

We prototype electronic components such as enclosures, connectors, bezels, buttons, sensor housings, and more. These are built using production-grade plastics with tight tolerances to meet functional, aesthetic, and assembly requirements.

Do you offer flame-retardant or ESD-safe plastics?

Yes, we offer both flame-retardant (UL94 V-0) and ESD-safe plastics. These materials are used to prototype control units, PCB housings, and other sensitive electronics requiring compliance with safety and static protection standards.

Can you support DFM or Moldflow reviews?

Yes. Our in-house engineering team provides DFM (Design for Manufacturability) and Moldflow analysis to optimise part geometry, minimise tooling issues, and ensure reliable mass production.

What's the minimum order quantity for soft-tooled runs?

We support low MOQs for soft-tooled production, starting from as few as 10 units. This makes our service ideal for pilot builds, product testing, or low-volume launches.