Description

Manufacturer of High Precision Plastic Components and Prototypes

Marcopolo is India’s first and leading rapid prototyping firm. Established in 1999 in Kolkata, the company has grown from a small rapid prototyping firm to a full scale manufacturer of engineered plastic parts today, based out of Pune. Situated in one of India’s key manufacturing belts, the company offers prototyping, tooling and injection moulding services for leading Indian and Global companies across sectors. The company has developed tailored solutions to help India’s growing manufacturing sector to validate their products during the R&D phase and produce high quality and precision plastic components.

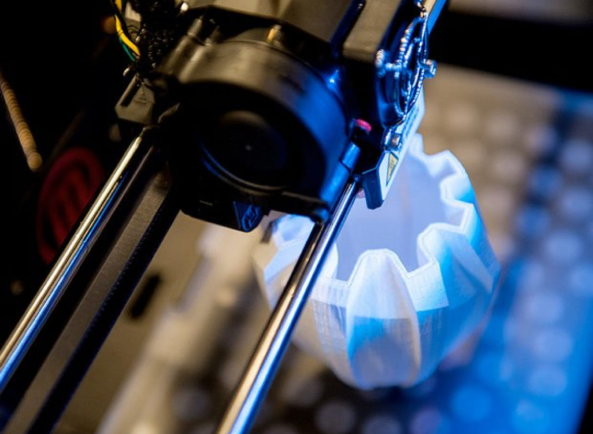

We offer end-to-end solutions to a company, right from the first fitment prototype to functional prototypes through to mass production with our in-house capabilities. We are a trusted partner of leading Indian and global companies across sectors, including Automotive, Defence, Medical Devices, Electronics, Drones, among others. We work with different departments within our clients’ organizations, and deliver custom manufacturing solutions for high precision and quality components.

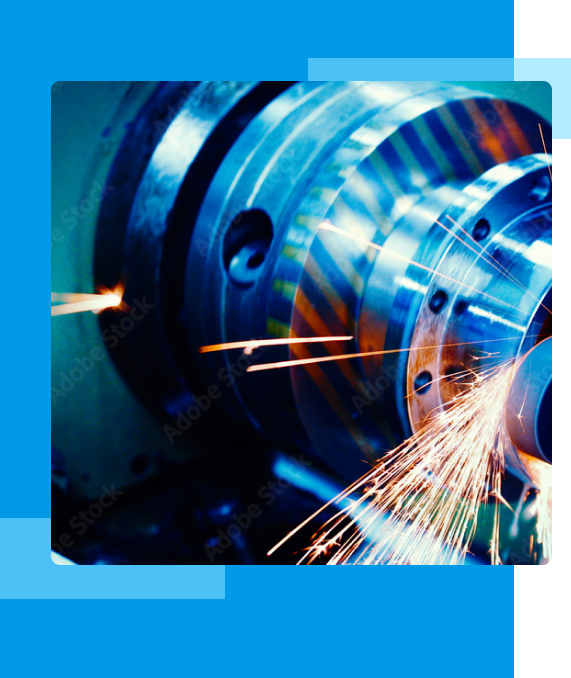

Our in-house facilities include rapid prototyping (3D printing, vacuum casting), tool room (soft and production tooling), and injection moulding machines with all supporting accessories. We have a paint booth and a dedicated assembly area where we assemble as well as test parts for our clients. We boast a strong partner network that adds strategic capabilities in our services. We offer a one-stop solution for our clients for other services including metal 3D printing, metal casting, vacuum forming, blow moulding, VMC machining, injection moulding (for high tonnage machines up to 1,500 tons).